尽管其高强度和耐用性性能,但复合材料仍然易于在役损坏。乐动娱乐官网了解综合损坏容差以减轻风险并确保材料适合目的是至关重要的。

Composite structures may be damaged during production or in-service, and those damages aren’t always visible during later inspections.

元素offers a variety of test methods that provide manufacturers with more insight into their composite materials’ damage tolerance and resistance and how that damage may grow during service. Two common methods are drop weight impact testing and fracture toughness testing.

Composite drop weight impact testing

Drop weightimpact testingassesses the damage resistance of the material against different impact energies. The method involves dropping a known mass from a known height, perpendicular to the face of a composite specimen.

Impact testing provides information about the resistance of a composite to impact damage and can be used in conjunction with Compression After Impact (CAI) testing to determine damage tolerance. CAI results show how an impact affects the subsequent compression strength of the material.

After impact, non-destructive inspection methods help measure the depth and size of the damaged area. Achieving Barely Visible Impact Damage (BVID) provides insight into the level force a composite can tolerate before it’s no longer fit for purpose.

Testing the fracture toughness of composites

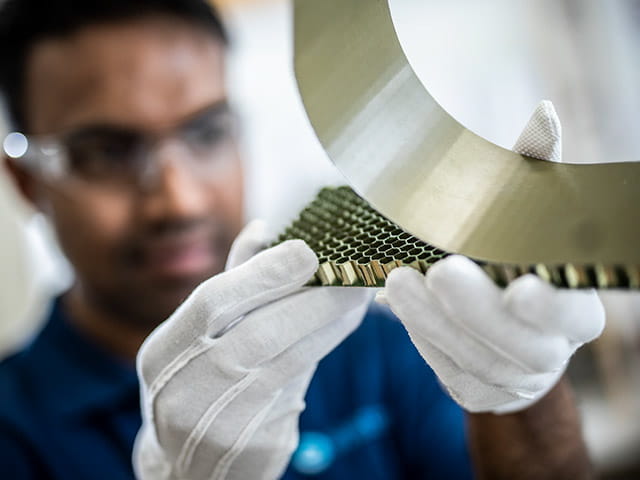

Composite materials have lower through-thickness tensile and shear strength than traditionally manufactured materials, meaning out-of-plane loading may cause delamination. Regardless of interlaminar strength,断裂韧性是一个决定分层进一步传播的可能性的财产。

Fracture toughness testing of composites involves using a specimen with pre-crack (e.g. a release film embedded within the laminate), that simulates an in-service crack. During testing, a load is introduced to force the crack faces apart in either Mode I (crack opening), Mode II (crack shear), Mode III (crack scissoring). Some test standards call for using mixed modes such as a combination of Mode I and Mode II crack growth.

Composite damage tolerance testing at Element

元素’s material testing experts have a breadth of experience in evaluating composite damage tolerance and durability. We work diligently to ensure your composites meet the requirements of relevant industry and custom test standards.

For more information on how we can help you better understand the damage tolerance of your composites or to request a quote, pleasecontact us today.

making certain for nearly 190 years

更多来自元素

Shear Testing of Composites

Our composite testing experts provide shear testing methods including interlaminar, in-plane, and v-notch to measure the shear properties of your material.

Read More

检查纤维增强复合材料乐动娱乐官网

Microscopic and macroscopic examination of fiber-reinforced composite materials helps ensure the quality of the material early in the manufacturing process.

Read More

Composites Testing

Find out how Element helps its customers to develop, test and qualify their composite materials to ensure that these complex, cutting-edge materials are safe, quality, compliant and ultimately fit for purpose.

Read More

Sign-up for free resources

Visit Element's email subscription center to receive the latest industry news, technical whitepapers, case studies, webinars, and upcoming events.

Read More