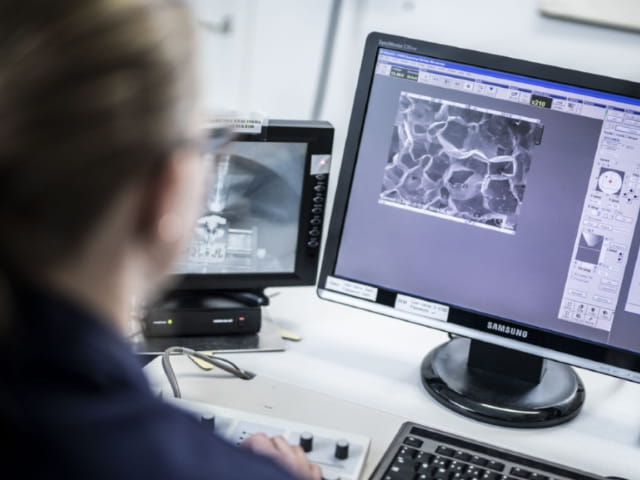

Microscopic and macroscopic examination of fiber-reinforced composite materials helps ensure the quality of the material early in the manufacturing process. Thorough material evaluations allow manufacturers to mitigate risk and save time and money.

During composite manufacturing, it is possible to introduce a range of unwanted specimen defects such as micro or macrocracks, resin rich areas, porosity/voids, and delamination through to fiber undulations, poor edge consolidation and telegraphing.

Fiber-reinforced composite materials investigations

Both microscopic and macroscopic examinations are useful methods for identifying defects in fiber-reinforced composite materials. These evaluation methods coupled with computer image analysis provide both qualitative and quantitative data without damaging the integrity of the material or part.

An in-depth microscopic examination is often carried out on a sample following an initial overall macroscopic examination of the part.

Composite testing at Element

Our composite material experts have a breadth of experience examining microscopic and macroscopic fiber-reinforced composite material samples. We work diligently alongside our customers to achieve their desired results by investigating materials according to their specific tolerances and pass/fail criteria.

For more information about ourcomposite testing services或请求报价,contact us today.

making certain for nearly 190 years

More from Element

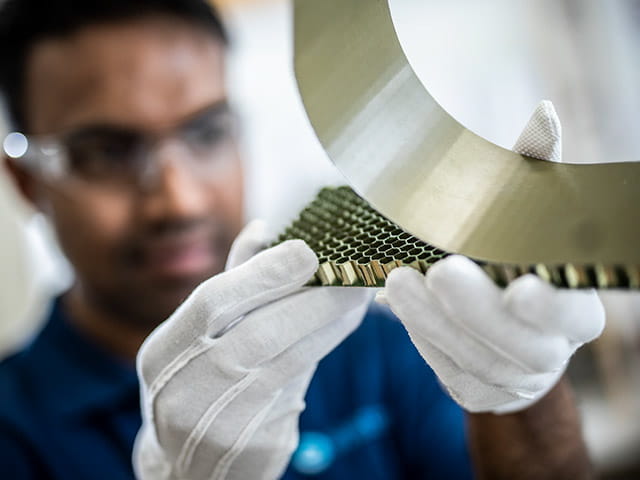

Composite Raw Material Testing

Element’s composite raw material testing helps manufacturers understand the physical, thermal, and mechanical properties of the constituents used to create their composite product.

Read More

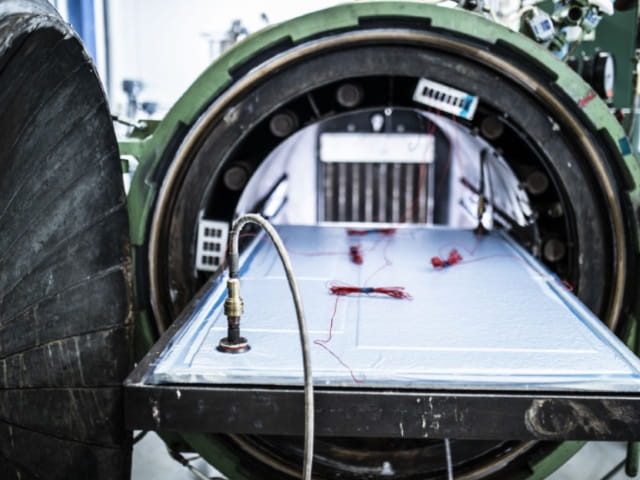

Composite Autoclave Curing & Fabrication

Composite curing autoclaves are a useful tool for fabricating a composite material with the desired properties. Our experts are ready to assist with your R&D or quality assurance needs.

Read More

Composites Testing

Find out how Element helps its customers to develop, test and qualify their composite materials to ensure that these complex, cutting-edge materials are safe, quality, compliant and ultimately fit for purpose.

Read More

Sign-up for free resources

Visit Element's email subscription center to receive the latest industry news, technical whitepapers, case studies, webinars, and upcoming events.

Read More