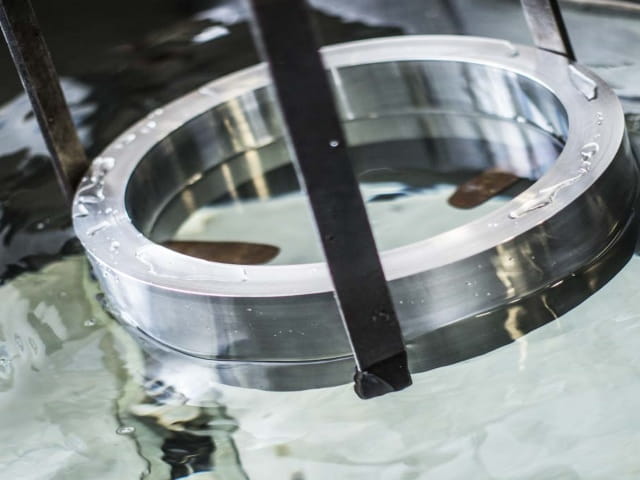

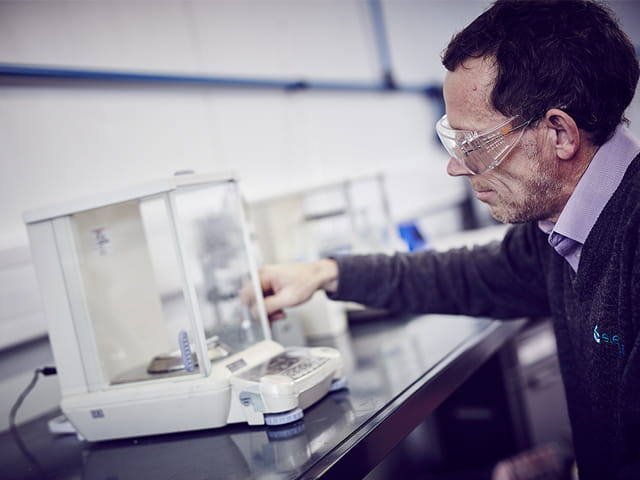

From routine quality checks to failure investigations, macroetch testing is an accurate, reliable method for assessing the metallic properties of materials ranging from stainless steel to beryllium. No matter your need, our highly trained metallurgists work with you to help understand your materials and get the most out of your products.

Our macroetch test services are offered at locations across the globe, and can be performed as standalone tests or as part of largermetallurgical testingprojects. We work with you to determine the best etching methods for your projects, giving you the reliable, accurate results you need to ensure that your materials are without defect and fit for purpose.

Our Macroetch Test Procedures

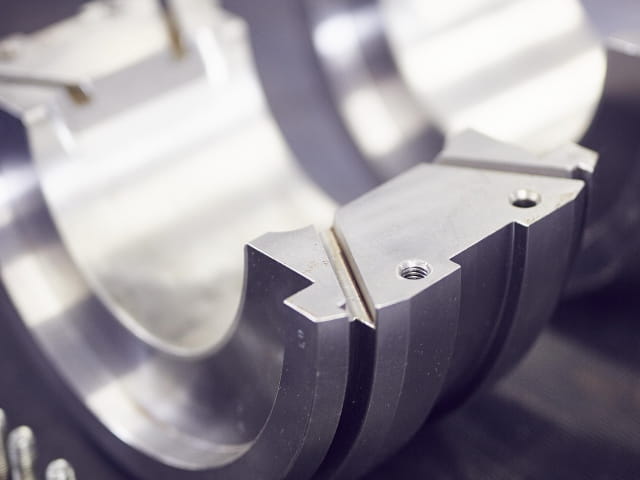

Depending the size of the available material and the standard being used, our labs provide several methods for macroetch testing. Using a mixture of chemicals and compounds, macroetching removes the top layer of a sample to reveal material characteristics, structural elements and potential defects that can be observed without the use of a microscope (or using very low magnification).

Some of the features that we look for in a macroetch test include:

- Banding

- Corrosion

- Fractures and defects

- Grain size and grain boundaries (grains must be large)

- Surface discontinuities

- Macro structure

- Forging defects

The Element Advantage

With global experts actively serving on professional and standards committees, including ASM and ASTM, we are consistently at the forefront of new testing techniques and material innovations. Our labs use state-of-the art equipment to ensure that your materials are fit for purpose and of the best quality.

For more information about our macroetch test services, or to request a quote,contact ustoday.

Our capabilities

Our Materials Testing Services

Abrasion and Wear Testing

Aerospace Fasteners

Aircraft Interiors Flammability Testing

Chemical Analysis

Chemical Processing

Composite Testing

Computed Tomography

Contamination Testing

Corrosion Testing

Die Steel Qualification

Differential Scanning Calorimetry (DSC)

Dynamic Mechanical Analysis

Eddy Current Inspection

Etching

Expert Witness Services

Failure Analysis

Fastener Testing

Fatigue Testing

FEA

Foam Testing

FTIR

Fractography Services

Fracture Toughness

Fuels and Lubricants Testing

Hardness Testing

Impact

Liquid Penetrant Inspection

Magnetic Particle

Material Properties

Mechanical Testing

Metallurgical Testing

NDT Field Services

Nondestructive Testing and Inspection

Nonmetals Failure Analysis

Nonmetal Mechanical Testing

Nonmetal Testing

On-site metallographic examination

Paint and Coating Material Testing Services

Passivation

Polymer Matrix Composite Testing

Polymer Testing Services

Positive Material Identification

Radiographic Inspection

Residual Stress Measurement

Residue Analysis

Sour Service Corrosion Testing

Stress Rupture and Creep Testing

Stress Strain Analysis

Tensile Testing

Thermogravimetric Analysis (TGA)

providing certainty for nearly 190 years

More from Element

Chemical Analysis

Find out how Element's chemistry teams work with our customers to identify the contents, composition and quality of materials they develop and manufacture.

Read More

Metallurgical Testing

Find out more about our metallurgical testing expertise and our comprehensive range services, from grain size analysis to fractography.

Read More

Materials Testing

Our materials testing labs are staffed by Engaged Experts working tirelessly to solve our clients' most complex technical and commercial challenges.

Read More

Element Locations

Learn more about our laboratories - where they are located; the unique capabilities they have and how they can help you solve your technical and commercial challenges.

FIND A LABORATORY