暴露于含有硫化氢(H2S)的流体的某些油田聚合物将在化学上变化,通过H 2 S浓度和温度测定劣化速率。由此产生的材料性能水平的不可逆变化可能对应用程序(例如,密封)部分的功能性能具有显着不利影响。元件’s dedicated sour service teams can evaluate the performance of elastomers, thermoplastics and composites in sour fluids in accordance with standards such as NORSOK (M-710), ISO (23936, 10423), API (6A, 16C) and NACE (TM0187, TM0296).

元件has more than 25 years of experience of delivering testing solutions for polymeric materials used in a huge range of Oil & Gas sector upstream and downstream applications.

H2S is a toxic gas present in many fields throughout the world, sometimes at very high levels. Seals and other polymeric components must be specified and qualified appropriately to established international standards. In addition, Element can offer significant experience in designing and executing custom sour fluid exposure programs to meet demanding client requirements for both material evaluation/qualification, and functional testing.

我们的订婚专家can evaluate non-metallic materials used in your offshore, renewable, and oil & gas applications. Our staff have contributed to both ISO and NORSOK standards development and are members of the relevant ISO Working Group committee. Element has run two internationally supported JIPs in the area of oilfield polymers: SOUR and SOUR2.

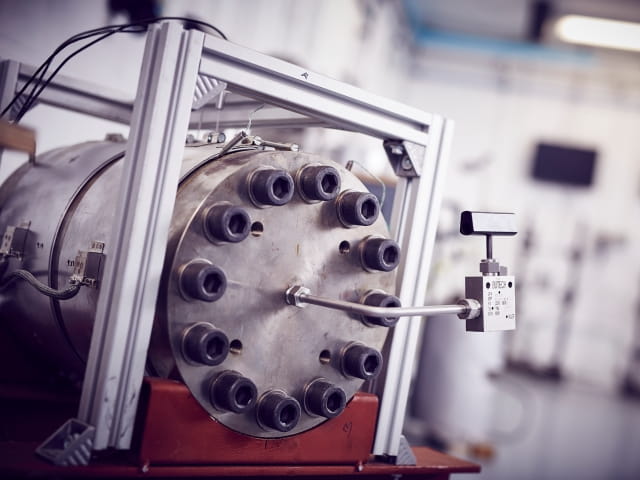

我们的酸液曝光能力

– World-class scale sour fluid exposure facilities in the UK and the US.

- 常规暴露于340巴和250°C,混合物含有高达30%H2S的混合物。

– Exposure temperatures to 320 °C in special vessels.

– Customer-specific services; consultancy, material and functional testing programs.

–Rapid Gas Decompression (RGD)用酸性气体混合物测试。

Our experts can work with you to advise on the most suitable testing methods for your materials, develop and review test protocols, build custom R&D programs, and evaluate components and systems to meet your project requirements.

有关我们的酸性服务功能的更多信息,或要求引用,contact us today.

我们的能力

Our Materials Testing Services

Abrasion and Wear Testing

航空航天紧固件

Aircraft Interiors Flammability Testing

Chemical Analysis

Chemical Processing

Composite Testing

Computed Tomography

Contamination Testing

Corrosion Testing

Die Steel Qualification

Differential Scanning Calorimetry (DSC)

Dynamic Mechanical Analysis

Eddy Current Inspection

Etching

Expert Witness Services

Failure Analysis

Fastener Testing

Fatigue Testing

FEA

泡沫测试

FTIR

Fractography Services

骨折韧性

Fuels and Lubricants Testing

Hardness Testing

Impact

液体渗透检查

磁性粒子

Material Properties

机械测试

Metallurgical Testing

NDT Field Services

Nondestructive Testing and Inspection

Nonmetals Failure Analysis

Nonmetal Mechanical Testing

非金属测试

On-site metallographic examination

Paint and Coating Material Testing Services

Passivation

Polymer Matrix Composite Testing

聚合物测试服务

积极的材料鉴定

Radiographic Inspection

Residual Stress Measurement

残留分析

Sour Service Corrosion Testing

Stress Rupture and Creep Testing

应力应变分析

Tensile Testing

Thermogravimetric Analysis (TGA)

Polymer Testing

我们提供聚合物,弹性体,热塑性塑料,复合材乐动娱乐官网料和结构粘合剂的世界级材料专业知识。

阅读更多

Sour Service Corrosion Testing

元件is one of a few ISO certified sour service labs in the world, providing sour service corrosion services for a variety of test types including NACE MR0175/ISO 15156.

Read More

乐动LOL

发现博客、文章、白皮书,webinars, and advice from our world-leading testing, inspection, and certification experts.

元件Houston

元件's Global Corrosion and Materials Technology Center for Metals and Polymers in the Energy sector

Read More