元素’s welding inspection and monitoring services ensure your welding meet required quality standards, leading to reduced failure rates and extending the potential operating life of components. Our welding specialists hold internationally recognized qualifications including the Certification Scheme for Welding Inspection (CSWIP), Personnel Certification in Non-Destructive Testing (PCN) and Certified Welding Inspection (CWI).

元素combines a global team of trained andcertified inspectorswith high-tech equipment to provide a complete range of third-party, independent weld procedure and weld engineering services for the Oil & Gas, Aerospace & Defense, Transportation, Power Generation, Construction, and Primary Metals industry sectors.

With the Certification Scheme for Welding Inspection (CSWIP) and Personnel Certification in Non-Destructive Testing (PCN) , our Certified Welding Inspectors (CWI), Certified Welding Engineers (CWEng) and International Welding Engineers (IWE) have in-depth knowledge and experience of manufacturing processes in all aspects of welding requirements to support your welding projects and staff.

Our CSWIP inspectors are qualified to 3.1 Welding Inspector and 3.2 Senior Welding Inspector levels with expertise involving ferrous and nonferrous materials.

Our approach to weld inspection and monitoring

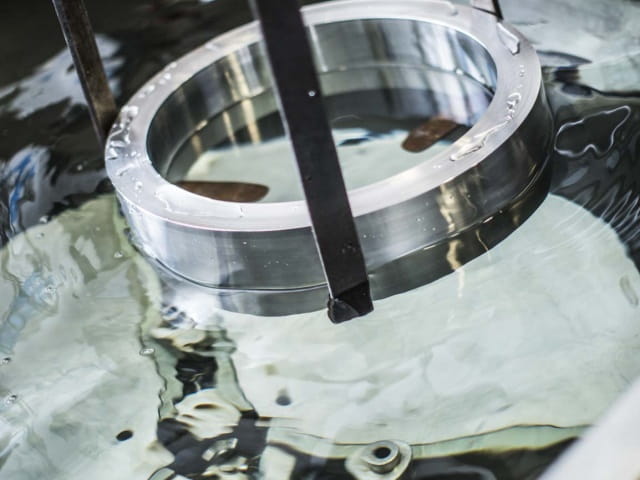

It is vital to detect any problems with welds before they escalate or soon after they occur so they can be corrected as quickly as possible. Element's CSWIP, PCN and CWP inspectors can evaluate the quality of welds at every step of the fabrication process prior to, during and after welding.

Following the authorization of the Preliminary or Proposed Weld Procedure Specification (pWPS) and the sourcing of the material and consumables, our CSWIP and PCN inspectors use calibrated equipment and data logging machines to confirm the joint configuration, set-up, temperatures and record all essential welding data of the new welding procedure.

Our CSWIP, PCN and CWI services

- Welding supervision

- Visual inspections

- Monitoring and approval of welding procedure specification

- Welding process auditing and improvement services

- Verification of welding equipment, documentation, and reports

- Welding Procedure Qualification Record (WPQR)

- Welder Performance Qualification (WPQ)

- Non-destructive testing

Third party witnessing

元素has forged strong working relationships with Certifying Authorities specializing in the oil, gas and marine industries, who recognize our strengths as a test laboratory with welding services and certification capabilities. If required, Element can organize witnessing on behalf of our customers.

For more information about how we perform welding inspection and monitoring , or to request a quote,contact us today.

其他能源服务

HPHT Exposure Testing

Non-destructive Testing and Inspection

Engineering Critical Assessment Services (ECAs)

Materials Characterization and Testing

Coatings Testing Services

Weld Testing

Our experts combine mechanical testing, quality evaluation, process assessments, and safety reviews to ensure that your welds and welding processes are safe, efficient and reliable.

Read more

焊缝检测服务

Find out how Element’s expert knowledge of welding techniques and welds helps our customers to understand how their pipelines are likely to behave once in situ and provide them with peace of mind and long term cost savings.

Read More

Ensuring the Quality of Laser Welds

Find out more about how to ensure the ongoing quality of laser welded parts.

Read more

元素的位置

Learn more about our laboratories - where they are located; the unique capabilities they have and how they can help you solve your technical and commercial challenges.

FIND A LABORATORY