Article

Metallurgical Failure Analysis Helps Prevent Future Failures

When components fail, it can affect the delivery of goods and the safety of the general public as well as result in costly repairs and downtime. Performing metallurgical failure analysis to understand why a part failed is critical to preventing future failures.

In the study of a failed part, the analyst must consider a broad range of possibilities for the failure. Although some faults can be attributed to a single primary cause, it is common for multiple secondary factors to contribute. The failure analyst must evaluate all evidence available to prepare a hypothesis about the causes of failure.

The most common type of failure studied is fracture. Fractures often have the most serious consequences, especially when load-bearing members lose their ability to carry their intended load. Other types of failures may be related to distortion, wear, or corrosion.

Failure analysis tools

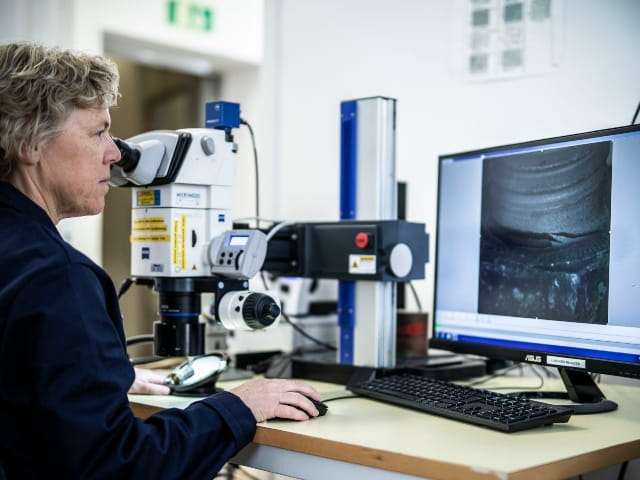

A well-equippedmaterials laboratorywill have most of the tools to effectively analyze these types of failures. These tools include a low-power stereomicroscope, metallographic equipment, hardness testers, spectrometers, and a scanning electron microscope (SEM).

The metallurgical failure analysis process

分析失败部分的过程从背景信息的集合开始。必须知道对部件和材料的指定要求是什么。该信息通常以零件图形的形式提供和参考材料规范。还要知道该部分的预期表现以及失败的部分与该期望相比如何是重要的。应向失败分析师报告对制造过程所做的任何更改。示例包括供应商更改,设计更改,材料更改,热处理变化等。

失败分析过程的下一步是金属部件的视觉检查。在目视检查中记录并拍摄的特点包括裂缝,骨折原点区域,部分损坏,残留物的存在,腐蚀产品和腐蚀坑。在某些情况下,nondestructive testingmay be warranted if cracks are not readily visible or if they may be present below the surface.Chemical analysis和hardness testing在大多数情况下确认是否执行part met the specified requirements. If enough material is available,拉伸试验和影响测试are desirable to help understand the inherent mechanical properties of the metal.

What the analysis reveals

Electron microscopy is a critical step in the失败部件的冶金分析. The electron microscope is the best means of verifying the fracture mode. Visual and low-power light microscopy is often not adequate to reveal the true morphology of a fracture. For example, consider the fracture surface of a bolt head. The fracture is relatively flat, which is often associated with fatigue cracking.

Closer inspection of the fracture origin region by a low-power stereomicroscope reveals a relatively rough texture, but the morphology of the fracture is still not clear. Examination of the fracture origin region via electron microscopy reveals a mixed fracture morphology of brittle intergranular cracking and dimpled rupture. The features revealed by the scanning electron microscope verifies that the fracture was not due to fatigue. Further investigation indicated the fracture was due tohydrogen embrittlement.

Metallography is an important step in themetallurgical failure analysisprocess.Examination of the microstructure can help verify whether proper thermal processes were applied to the part. Metallography can also identify whether material anomalies were present in the material that could have had a deleterious effect on the part’s performance.

All the pieces of the puzzle

After all the information is collected, and the analysis is complete, a conclusion can be made based on the evidence available.

The investigation can be thought of as a forensic puzzle. The more pieces of the puzzle that are in place, the more conclusive the test results will be. It is often tempting to ask the metallurgist to minimize the amount of testing performed to save time and money. It may also be tempting to withhold background information about the part for fear of biasing the metallurgist’s final conclusion. It should be understood, however, that restricting the amount of testing and withholding important information will effectively take away pieces of the puzzle that can prove critical to achieving the correct final conclusion. If the reasons for failure are not properly understood, corrective actions to prevent future failures may be ineffective.

For more information on metallurgical failure analysis, or to speak with one of our experts,contact us today.

View more articles aboutAerospace Testing ServicesMore SectorsEnergyTransportation Testing Services

通过介绍与您的相关文章Nucleus