疲劳试验in the Automotive Industry

By Engaged Expert

Dr. John Tartaglia

什么是疲劳测试?

Fatigue is anything that involves alternating, or cyclic, stress or strain, and this loading can cause damage or cracking at stresses that are well below the yield strength of the material or component.

We refer to cycles of 100 to 10,000 as low cycle fatigue (LCF), and more than 10,000 is referred to as high cycle fatigue (HCF). This can be significant given that cars, or their components, may well have many millions of cycles.

汽车领域的乐动娱乐官网疲劳最常用的材料和零件是什么?

在材料方面,汽车扇区主要乐动娱乐官网用于结构部件的钢,铸铝用于气缸体和头部,以及曲轴的铸铁。铝越来越多地包含在车身板和车辆的结构部件内。也就是说,由于所涉及的负载和温度,诸如卡车的较大车辆可以在诸如头部和块的部件中使用铸铁。然而,钢和铝是越来越多的方式形成:液压成形以产生管状部件的目的是减少与较旧的固体杆或板结构相比材料的重量。乐动娱乐官网

出于疲劳测试的目的,我们可以将材料用用入车辆和动力系的结构部件。乐动娱乐官网汽车的结构部件包括门和运行板的中心支柱。其他结构部件包括框架,保险杠,支架,发动机支架,座椅零件,座椅靠背和轮子,所有这些都是从振动的角度测试的材料和组件水平上的测试,同样像碰撞价值一样多。由于费用和复杂性,头部和块通常不会疲劳;头部和块通常是用优惠券样本测试的疲劳,这些样品是已经从部件中切除和加工的测试标本。然而,曲轴和整个发动机仍然仍然经过测力计测试,具有严重的过温和负载条件。

疲劳测试在测试不同材料时如何不同,复合材料与金属?乐动娱乐官网

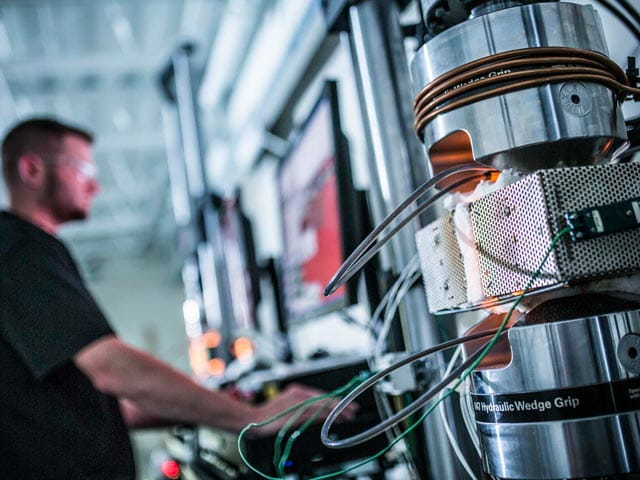

Within automotive manufacturing,聚合物基质复合材料(PMC)使用碳纤维增强聚合物(CFRP)。与金属相比,这些材料为疲劳测试提供了有趣的挑战。乐动娱乐官网从建立测试本身的角度来看,复合测试需要先进的加工技术,以避免纤维拔出,敏感的载荷电池测量低负荷和先进的夹持技术,以避免金属不发生的抓地骨折。

由于他们的各向异性性质,PMCS呈现了另一个挑战。这些材料的性质随方向而变化,因此涉及毯子方法的叠乐动娱乐官网层技术旨在去除各向异性。结果,任何疲劳测试都需要考虑叠层结构的装载方向。

是否有可能导致变化的材料,技术,方法或工具的趋势?乐动娱乐官网

虽然内部基本原则疲劳试验have not changed in the last fifty years, specimen testing has certainly undergone a significant overhaul. Digitization of the test control and analytical data for strain life fatigue information has been the biggest change in fatigue testing.

A very significant development, which is gaining traction within the industry, is the increasing prevalence of "just-in-time" manufacturing methods. This has prompted manufacturers to assess how they can reduce the time taken in the fatigue testing stage. Naturally, long testing cycles require specific time frames, and accelerating fatigue test frequency will have consequences on the temperatures generated in the fatigue test sample, which may alter the results and conditions required.

Within the industry, the ultimate goal is to add very-high cycle fatigue (VHCF) tests to the current LCF/HCF testing, which will more accurately predict long-term fatigue life within the automotive sector. VHCF methods involve quite a radical re-think to fatigue testing. VHCF test development currently involves passing sound waves through samples, rather than current techniques applying fatigue strains to samples with moving servo-hydraulic actuators.

另一个重大改变我们努力is the modeling of fatigue testing of materials. Models are predicted to introduce virtual casting and testing processes, which is a major change in the industry. These virtual processes will inevitably deliver significant savings on current physical metal processing and test methods, as certifying materials requires significant expense.

生命预测是一个大型研究领域,这将使制造商能够修改他们的流程,以便快速为材料提供增强的性能,并改善其产品和车辆的性能。乐动娱乐官网

新的制造技术,如3D printing, will present new challenges. Ultimately, we can't accurately predict the huge range of fatigue resistance benefits (or perhaps disadvantages) from these materials at this stage. As we gather more information about their manufacture and performance, we will see an increase in their use.

Find related articles to you through the核

近190年的肯定

More from Element

疲劳试验

了解元素的疲劳测试实验室如何帮助公司满足质量要求,并创造更安全,更强大,更成功的零件和产品。

Read more

乐动娱乐官网材料测试

Our materials testing labs are staffed by Engaged Experts working tirelessly to solve our clients' most complex technical and commercial challenges.

阅读更多

John Tartaglia

Dr. Tartaglia has been performing materials characterization and failure analyses for more than 25 years and is a materials expert in wrought steels, aluminum and magnesium.

阅读简介