EMC Principles made easy

By Engaged Expert

Steve Hayes

Electromagnetic Compliance (EMC) is often described as a ‘Black Art’ but the key to unlocking it is to understand its basic principles. Once these have been learnt, EMC can suddenly appear much simpler.

当一个产品设计——无论是自然史l product or a system – it is important to ask what needs to be considered to ensure EMC is achieved. In order to do this, it is essential to take a step back to basics and consider how EMC interference is actually generated.

In the simplest of terms, interference is caused by moving from one state of energy to another. As with the flick of a light switch, we have come to expect this transfer of energy to be instantaneous. EMC regulations, fromcommercialtomedicaltomilitary, are essentially all asking how to stop the voltage overshoot or undershoot which takes place during this transfer of energy so that a product can function without interference.

Ask the right questions

It is the probability of such interference which has to be identified. No matter how much electromagnetic noise is generated, it must be remembered that there has to be someone or something receiving that noise for interference to occur. The key questions which must be asked are:

- Where is this product going to be used?

- With what/whom is it going to interfere?

- How will the energy travel from the product to its “victim”

Energy will travel either down the cabling or through the air, the two mechanisms therefore being radiation and conduction. This is why the standards used are based around radiated and conducted tests.

There are other mechanisms of which to be aware, such as capacitive coupling and induction. These are more unusual, even though induction is predicted to increase in significance as new technologies, such as wireless charging of electric cars and appliances, continue to emerge and become more widely adopted, the potential interference that they cause is limited.

Take three key factors into account

Whether it is a product, a system or a printed circuit board, the basic EMC principles remain the same. When considering how the design of the product could ensure greater electromagnetic compatibility, there are three key factors to take into account:

- Shielding

- Earthing

- Filtering.

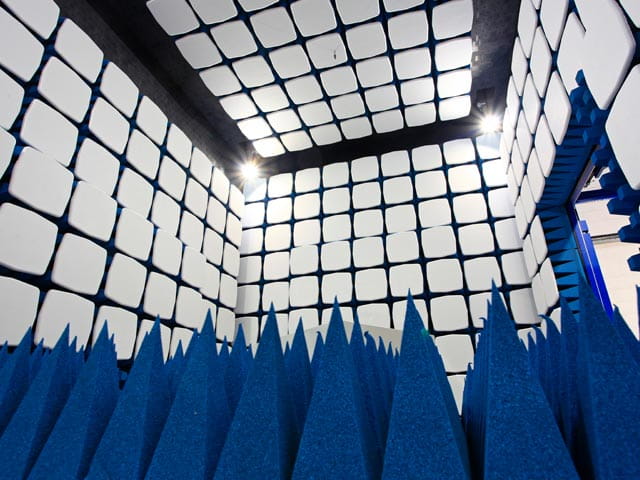

When reviewing the shielding we think of metal boxes or shielded cables – things that provide a Faraday Cage. It is essential to make provision for 360° of complete continuity of the Faraday Cage – from good conductivity of the product's housing to its lid or termination of cables. Once sufficient shielding has been achieved, more energy will inevitably be pushed out via the cabling so appropriate filtering must now be considered. Finally, earthing, or how the energy will travel from a high potential to the earth/ground, must be factored into the equation.

Element regularly sees products fail because of the failure to fully take into account one or more of these three factors. It is for this reason that we now offer anEarly Stage Qualification (ESQ®)service to support manufacturers through the complex nature of qualification testing and to allow for a smoother approvalsjourney. ESQ is essentially making sure that the shielding, filtering and earthing is considered early in the design process rather than at test point when failure becomes more likely. Time and time again, we have seen how an early investment at the front end enables the manufacturer to make substantial savings when they reach the test stage.

Qualify the prototype design early in the development cycle

The most cost-effective approach to product development will always be to qualify the prototype design early in the development cycle. A key target should then be to achieve success first time at the testing, approvals and certification phase. If a product has to be re-designed it can be prohibitively expensive, resulting in delays to market and a loss in consumer confidence.

Consider where the product may be exported early in the design process

Whilst many countries have adopted regulations that are almost identical toCE Marking, once a product is to be exported it becomes much more likely that mandatory third party testing will also be required. It is therefore vital to considerwhere the product may be exported toas early as possible in the design process, taking advice if necessary. Modifying a product later on to meet unforeseen export requirements can be a costly and time consuming exercise and is a common mistake.

CE Marking has now been a legal requirement for over twenty years yet thousands of products still fail every year. Test houses such as Element will continuously be asked to provide guidance and advice on EMC compliance, be it at the beginning or the end of the design process. However, early advice to prevent issues arising later will always be the safer and more cost effective option.

For more information on ESQ and EMC compliance, pleasecontact usor call UK +44 808 234 1667 or US +1 888 786 7555.

View more articles aboutMore Sectors

Find related articles to you through theNucleus

making certain for nearly 190 years

More from Element

EMC Testing

EMC testing for aerospace, military and commercial applications. Laboratories in the UK and USA.

Learn more

CE Marking and Testing

CE marking is a mandatory conformity mark enabling you to enjoy free movement between all 28 Member states.

Read more

Advisory Services

我们的团队of Engaged Experts can help you understand the various regulatory requirements and reduce the test burden by comparing the various standards and producing compliance strategies that fulfill the brief of ‘test once, approve to many’.

Read more

Product Compliance

Element provides one of the widest range of test and support services in the world aimed at getting your product to market and complying with the V&V requirements.

Read more