文章

医疗器械腐蚀测试每ASTM F2129

The human body and its immune and inflammatory mechanisms can create an aggressive environment for metallic implants resulting in implant rejection and failure (Gilbert, Corrosion, 2017;73(12):1478-1495). In vitro testing of small implants is typically performed per ASTM F2129 to mitigate these risks. While this testing helps determine implant susceptibility to corrosion, it does not take into account the effects of cells, proteins, and other biological effects that implants will experience in vivo.

尽管其限制,ASTM F2129自2001年原始出版物以来,ASTM F2129经历了多项修订,以更好地协助医疗器械制造商评估其小植入物的抵抗和缝隙腐蚀。该标准提供了一种用于在整个器件上进行循环(正向和反向)电位动力学偏振测量的测试方法,以最终形式和完成。

在下面的部分中,我们描述了test methods那仪器那结果and验收标准used in vitro corrosion testing of small implants.

Test Apparatus

A typical multiport electrochemical test cell is used for testing. It has inflow/outflow ports for the nitrogen gas and heated water circulation, ports for the reference, graphite counter and working/sample electrodes, and an inner chamber for the saline bath.

附加组件包括:电位器,计算机,pH计,氮气罐,水泵,带有紫外灯和固化的掩模的导电环氧树脂,以及用于样品附着的不锈钢线。磷酸盐缓冲盐水等试剂用于浴,异丙醇和II型试剂级水用于样品漂洗。光学和电子扫描显微镜用于测试前检查和后测试检查。

测试方法

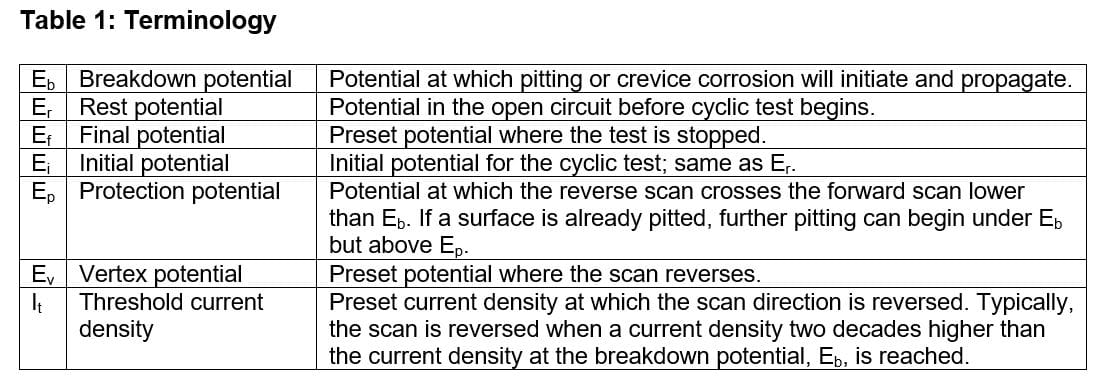

表1提供了简要术语摘要;有关详细信息,请参阅ASTM F2129标准。

简而言之,将植入物在37±1℃下在盐水中保持在右侧7.4±0.2的开始pH值。在植入物和参比电极之间引入电位,并升高到生理潜力上述。击穿通常将导致电流密度快速增加,如潜在与日志电流密度的输出图。需要计算或估计暴露于溶液的样品的总表面积,从而可以确定由样品产生的电流密度。

Samples are prepared for testing and thoroughly inspected. Any preconditioning should be performed as it can impact the behavior of the implants. Conductive epoxy is used as the interface to the sample (specimen holders vary depending on the device type), connected to a potentiostat through a wire, and resistance is checked to ensure good connection. The test cell is filled with saline (minimum of 500 mL, typically 1L), heated to the target temperature, and nitrogen gas flow at 150 mL/min is initiated. Nitrogen gas flow is used to deaerate the solution and lower dissolved oxygen concentration to decrease the potential at which oxidation and reduction currents are equal.

Temperature, pH, and nitrogen gas flow time (30 min minimum) are recorded, then the device is rinsed and inserted in the test cell with the wire. Saline is added into the reference electrode holder, and the electrode is inserted at 5mm or less from the sample, but not in contact with the sample. The nitrogen purge is continued throughout the test. The open circuit test is initiated, and ER.在1小时后记录。然后,通过设置e以1 mV / s扫描速率启动循环偏振测试一世and EFto ER.。循环极化密切监测;如果a current density increase larger than two decades occurs, voltage is reversed.

When the test is completed, the final temperature, pH, ER.,E.B.,ef和eP.被记录。将样品从测试中取出并冲洗,将线夹在样品上方〜1英寸,并将样品储存以进一步测试后检查。虽然该标准并未指示应测试有多少样品,但我们通常会看到每个表面光洁度的3-8个样品。

试验结果

每个样品记录测试条件:氮流动时间,初始温度,初始pH,最终温度和最终pH值。样品测试结果通常以表格和图形格式提供。还提供了预先和测试后的观察结果和检查结果。

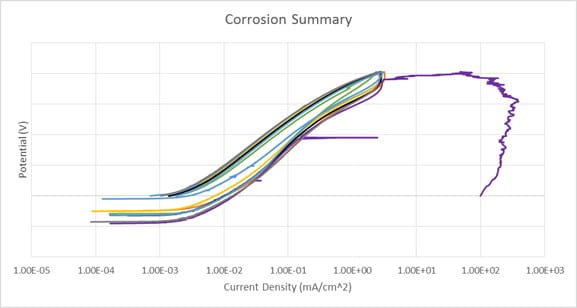

上图所示的图表显示了纳米酚器件的8个样品的腐蚀试验结果绘制为电位(MV)与记录电流(A)。结果显示了8个样本之间的一致性;随着电流密度的增加,紫色数据集是故障潜力的示例。

验收标准

ASTM F2129没有定义验收标准,但识别eB.作为上面的关键数据点,凹坑成核并增长。因此,越高B.一世s, the more resistant the metal is to pitting corrosion. It is also recommended that EB.将值与谓词器件的值进行比较,该谓词装置在体内作为参考中显示出良好的耐腐蚀性。设备制造商为其植入物定义验收标准。在我们的经验中,可以接受eB.值最常见于300 mV以上,它们通常设置得更高的阈值。

Consultation

We often perform corrosion testing on medical devices to characterize their corrosion potential. If you would like more information about our医疗器械腐蚀测试services, or for assistance with your device’s corrosion and/or fatigue testing,联系我们订阅的专家讨论我们如何提供帮助。

元素提供最广泛的医疗设备测试范围,因此如果您正在寻找这样的服务包测试那microbiological analysis那加速老化 - 保质期测试或EMC / EMI测试,与我们联系以连接正确的实验室。

Find related articles to you through the核

近190年的肯定

More from Element

医疗设备

As a comprehensive testing partner, you’ll enjoy the benefit of a single supplier source for all of your testing needs, from mechanical testing and environmental simulation to EMC and wireless device testing.

阅读更多

可重复使用的医疗设备验证

Our medical device experts evaluate the environmental impact on the identification markings and function of reusable medical instruments after repeated autoclave sterilization cycles.

阅读更多

医疗设备测试提示

为医疗设备测试程序准备可能对许多制造商来说是一个挑战,特别是如果它是一个新的或新产品,或者时间是有限的。我们的医疗设备专家分享其测试技巧和最佳实践。

阅读更多

Sign-up for free resources

访问元素的电子邮件订阅中心,以获得最新的行业新闻,技术白皮书,案例研究,网络研讨会和即将到来的活动。

阅读更多