文章

ASTM F2028: Preventing Glenoid Component Failure in Total Shoulder Replacement

Total shoulder replacement, also known as total shoulder arthroplasty (TSA), has become increasingly common with more than 50,000 surgeries performed per year in the US and expectations for this number are that it will continue to increase. There are numerous reasons why patients undergo total shoulder replacement surgery, including forms of arthritis, severe bone fractures, and/or excessive soft tissue damage.

Originally, the objective for shoulder replacements was to relieve pain after non-surgical approaches were exhausted. As the materials, implant design, and surgical procedures advanced, the objective transformed into not only relieving pain but restoring function and increasing range of motion in the joint.

总肩部更换设计

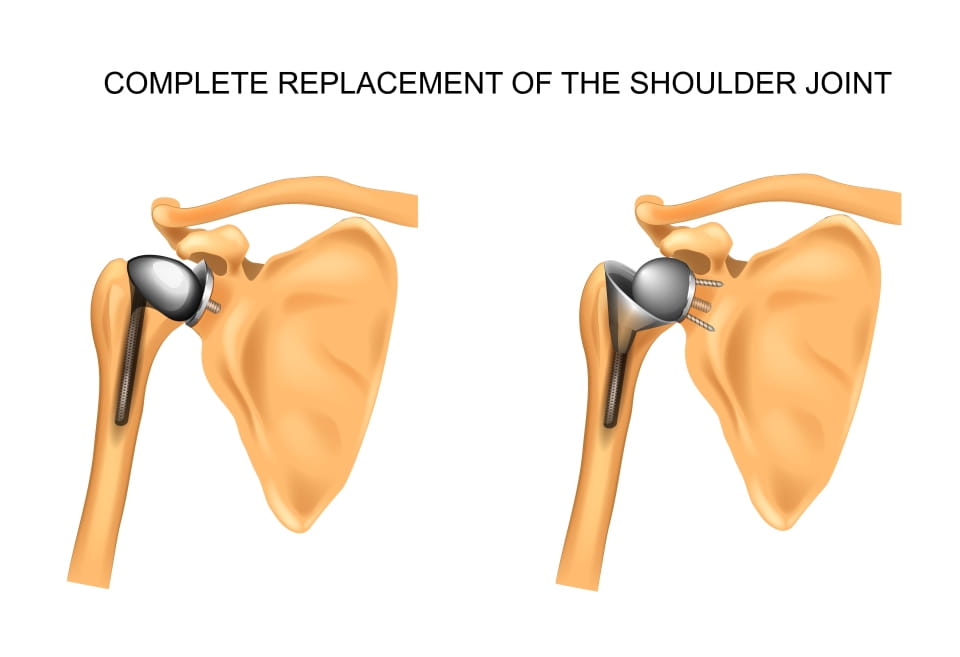

有许多不同的总肩关节置换植入物设计,其中两种主要成分被替换(肱骨和关节盂部件);但是,这些植入物下降了两种类别,解剖和逆向肩部。

Both of these configurations, like most orthopedic implant devices, have their challenges once implanted. Typical failure modes for TSA include:

- Infection – Infection caused by the surgical procedure itself.

- Rejection – The body does not have a desirable reaction to the newly implanted device. It is recognized as foreign and the body rejects it through numerous immune system responses. This is also commonly caused by fretting and corrosion of modular devices that release harmful metal ions into the body.

- Fracture – Fracture to any of the device components such as the humeral stem, polyethylene glenoid, and humeral liner backing. Disassociation between mated components and fracture to the patient bone can occur.

- 不稳定性 - 肱骨和关节盂部件可以经历逆转和/或止动或肱骨部件偏移。骨粘附差或骨量不足也可能导致不稳定。

- Aseptic Loosening – One of the most common failures is loosening of the glenoid component.

在这些设备被带到市场之前,他们必须受到各种各样的测试,以证明他们是安全的,而且不容易受到列出的失败模式。生物相容性,机械互锁,机械疲劳,fretting corrosion, porous coating evaluation, and loosening testing are some of the tests performed for TSA devices. The FDA published theClass II Special Controls Guidance: Shoulder Joint Metal/Polymer/Metal Nonconstrained or Semi-Constrained Porous-Coated Uncemented Prosthesis文档提供评估这些设备的方向。此外,创建了以下ASTM标准,以评估不同设备组件的性能。

- ASTM F2028 – Standard Test Methods for Dynamic Evaluation of Glenoid Loosening or Disassociation

- ASTM F1829 - 剪切中解剖视网型锁定机构的静态评估标准试验方法

- ASTM F1378 – Standard Specification for Shoulder Prostheses

- ASTM F1044 – Standard Test Method for Shear Testing of Calcium Phosphate Coatings and Metallic Coatings

- ASTM F1875 – Standard Practice for Fretting Corrosion Testing of Modular Implant Interfaces: Hip Femoral Head-Bore and Cone Taper Interface

这些标准中的大部分与其他总关节相当,例如髋关节和膝关节,几乎与肩部部件有关的具体细节。然而,ASTM F2028标准特定于肩部替代设计,通常被称为“摇马”测试。该方法提供了动态评估解剖和反向肩部配置的方向。

ASTM F2028 test method

The objective of ASTM F2028 is to evaluate the susceptibility of the glenoid component to loosening by quantifying the edge liftoff or pivoting of the component before and after cyclic testing. For both anatomic and reverse configurations, the devices should be in their final manufactured state with any polyethylene parts having been sterilized according to the manufacturer’s specifications.

将盂组分组装成骨替代品,通常是聚氨酯,密度范围在25-30磅/英尺之间3.(closely representing the average strength of glenoid cancellous bone), using standard surgical techniques. If cement is used in preparation, it is important to allow for curation.

解剖肩部测试

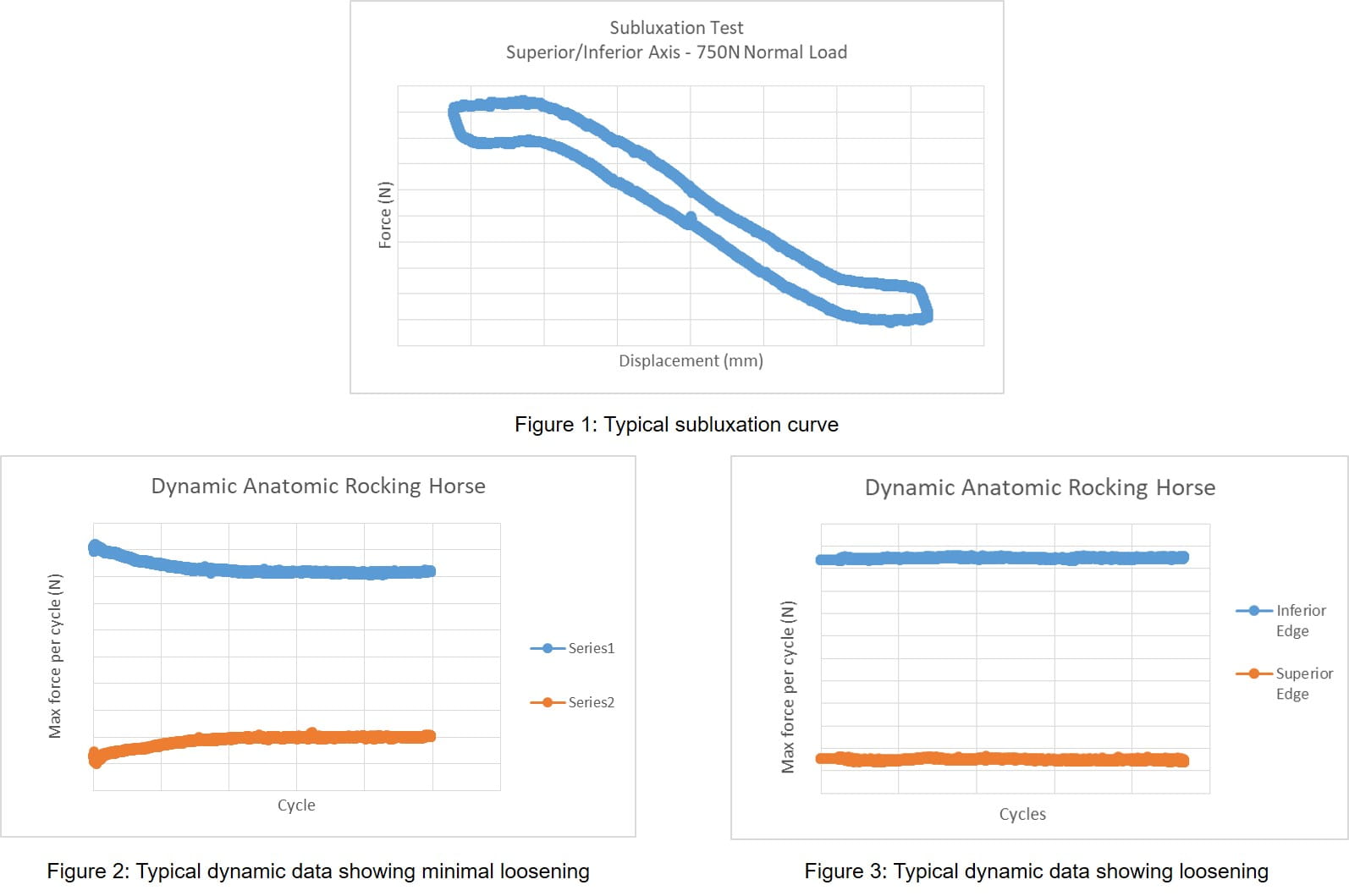

在循环测试之前进行两个子柱测试,以量化Sublux关闭关节盂部件所需的剪切力和位移。使用双轴试验框架,压缩力(通常为750n)通过肱骨头施加到关节盂部件并垂直于关节盂平面,然后肱骨部件平行于上/劣质(S./ i)或关节盂组分的前/后(A / P)轴。这通常产生类似于图1(下面)的剪切力 - 位移图。

Prior to cyclic testing, edge displacements or the amount of rocking seen in the glenoid assembly are measured. This is measured at three separate positions; the neutral location (location where no shear load is seen in the system when the humeral head is resting on the glenoid with preload), 90% of the subluxation translation in the superior/anterior direction, and 90% of the subluxation translation in the inferior/posterior direction. Cyclic testing is then performed in deionized water at 37C, typically between 1-2Hz, for 100,000 cycles or until failure has occurred. The test is a displacement controlled function with a distance of 90% of the superior/anterior and inferior/posterior subluxation translation measured in the subluxation test. This will typically result in a peak force versus cycle graph as shown in Figures 2 and 3 (below). Figure 2 shows no decrease in peak load typically indicating a firmly fixated implant while Figure 3 shows a decrease in peak force typically indicating loosening of the glenoid component.

可以制造对这些参数的变化,例如增加的周期数或执行力控制测试而不是位移控制;但是,这种变化可能偏离ASTM F2028。完成100,000个循环后,再次采用相同的边缘位移测量以进行测试后比较。该方法建议至少三种标本。

Reverse shoulder testing

在评估反向肩部结构时,不需要在循环测试之前不需要静态测试。类似于解剖结构,执行预先测试的边缘位移测量。制造这些测量,同时将350n平行于面孔平面的剪切力和通过旋转中心的轴向压缩载荷,垂直于面孔平面。虽然加载,如下所示,在剪切和轴压压缩方向上进行位移测量。

The load is removed from the construct and measurements are taken again. This is repeated for a minimum of 3 cycles. After these initial measurements, cyclic testing is performed in air with fan cooling and/or with light lubrication. A compressive force of 750 N is applied through the humeral liner while the glenoid is rotated in the superior/inferior axis about its center of rotation, for a minimum of 10,000 cycles or until glenoid component failure occurs. A minimum rotation of 45 degrees is required (± 22.5°). Following cyclic testing, edge displacement measurements are repeated. Similar to the anatomic approach, a minimum of three specimens should also be tested. In the current standard, ASTM F2028-17, acceptance criteria are not given for either the anatomic or reverse with regards to edge displacements. Failure is determined by disassociation of the glenoid insert.

Custom methodology

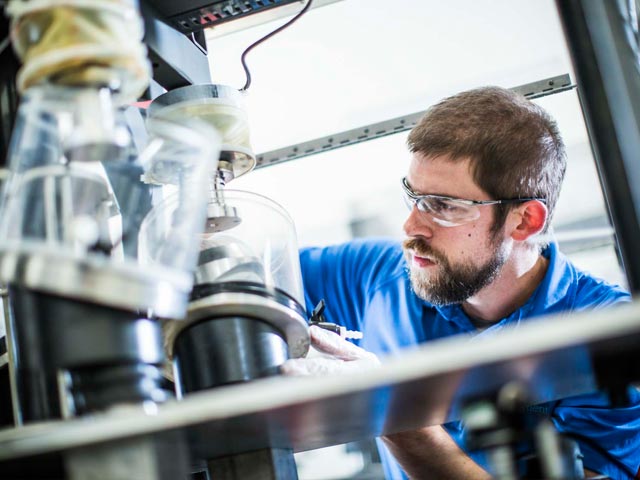

Element has developed custom test machines for total shoulder arthroplasty testing, including two options for anatomic rocking horse testing. Each has an electromechanically actuated horizontal (in reference to the bench top) linear translation and a method to apply a joint compressive force perpendicular to the glenoid plane. The humeral head is attached to the horizontal axis and provides the superior/inferior or anterior/posterior translation.

两个测试机器不同的方法使用for applying this force. One machine has a dead weight system approach making use of hanging weights. The other uses electromechanical actuation, enabling custom, variable-loading scenarios.

The test machine used for reverse shoulder testing is also a biaxial electromechanically actuated machine. The horizontal axis is a rotary axis while the vertical axis is linear. Again, both of these axes are controlled enabling custom loading/displacement profiles.

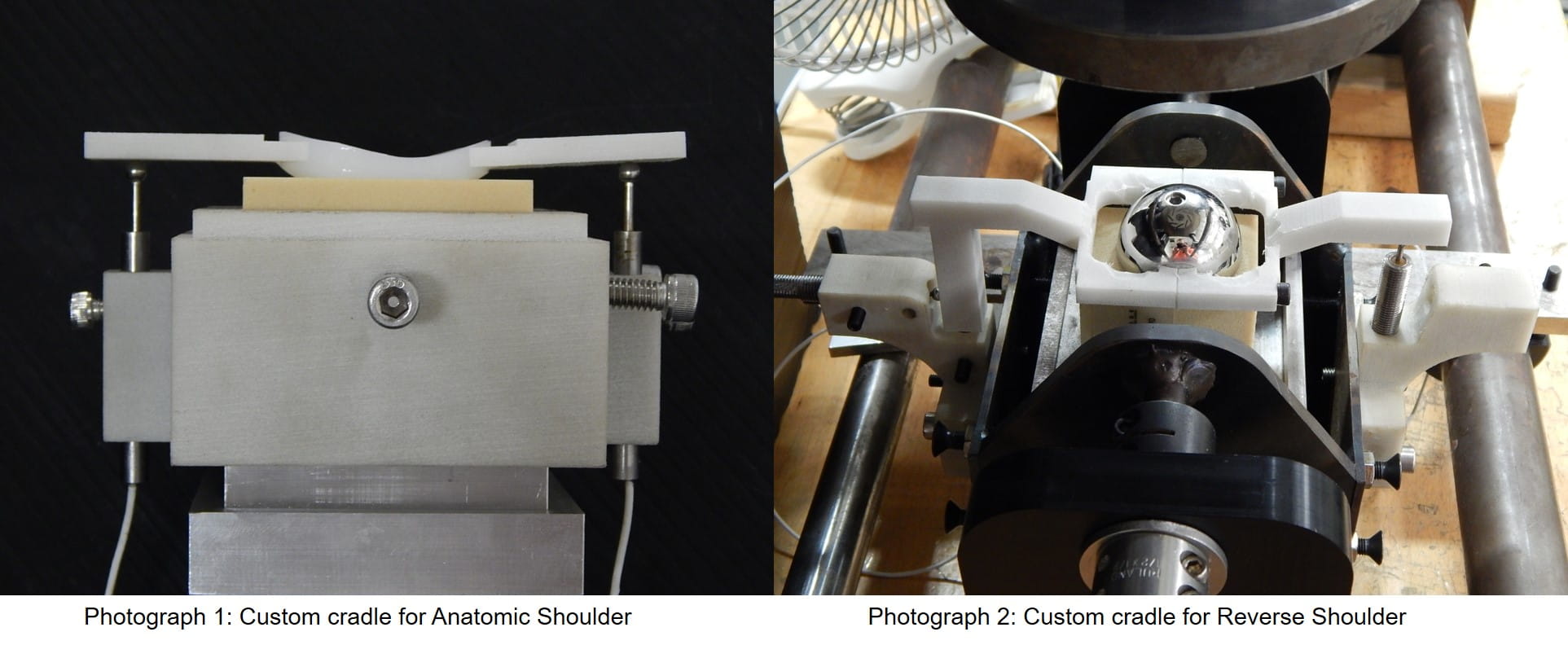

还实施了定制夹具,以允许种植体的各种设计和尺寸和测量边缘位移。对于解剖学测试,肱骨头通常粘合到支撑夹具上,该支撑夹具拧到测试框架的水平斜面上。胶合板和骨替代组件采用加工,以适合我们的定制摇篮。支架允许通过使用固定螺钉在前/后方向上对准,同时支撑上级/下端。摇篮还含有用于测量边缘位移的DVRT传感器的机加工插槽。为了进行这些测量,为每个植入物制造定制3D印刷平台。这些平台模仿关节盂部件几何形状,并且可以用粘合剂固定到关节盂边缘。然后,DVRT传感器可以在这些平台上休息并测量边缘升降机前,柱和循环测试期间(下面,照片1)。

类似于解剖的方法,当测试the reverse configuration, we use a custom made cradle that allows for rotation of the glenoid/bone substitute assembly. The cradle has attachments for DVRT sensor incorporation. Dissimilar to the anatomic method, these attachments allow for two DVRT sensors at each implant edge instead of one. ASTM F2028 requires the reverse configuration to have edge measurements to quantify both the axial liftoff distance and the displacement in the shear direction. Custom 3D printed DVRT platform attachments are designed for each implant and attached through a clamping technique or by use of an adhesive (above, photograph 2).

Conclusion

With the projected increase in total shoulder arthroplasty procedures, Element has pioneered methodologies to evaluate these devices and mitigate the risk of glenoid component failure. As the market continues to demand new technologies, the ability to modify and customize these tests methods is critical. Alongside methodology development, Element partners with our customers and standards organizations to meet their needs and ensure success.

If you have questions about our medical device services or how we can assist with your testing needs,contact our experts今天。

近190年的肯定

More from Element

脚,脚踝和肩部更换植入物测试

With a wide range of services, we are a single source provider for foot, ankle, extremity and shoulder implant testing.

阅读更多

医疗设备的测试协议

议定书和计划将减轻您的风险,防止混淆,设置明确的期望,并保留未来参考和使用的必要信息。

阅读更多

Preventing Fretting Corrosion of Orthopedic Devices

The human body is a corrosive environment that can compromise the performance of orthopedic devices. The test methods outlined in this article aid in preventing fretting corrosion in your device designs.

阅读更多

Medical Device

As a comprehensive testing partner, you’ll enjoy the benefit of a single supplier source for all of your testing needs, from mechanical testing and environmental simulation to EMC and wireless device testing.

阅读更多