Article

模拟使用预处理支架进行疲劳试验

Simulated use testing of implantable cardiovascular medical devices is a well-established non-clinical engineering test used to serve many purposes including delivery, deployment and retraction of a stent, particulate evaluation, and surgeon training.

The FDA’sNon-Clinical Engineering Tests and Recommended Labeling for Intravascular Stents and Associated Delivery Systemsdocument outlines performing simulated use testing by tracking the device through an in vitro fixture, and mimicking challenging in vivo conditions (e.g., a tortuous path, aqueous environment).ASTM F2394-07 (2017) – Standard Guide for Measuring Securement of Balloon Expandable Vascular Stent Mounted on Delivery Systemprovides further guidance with an example of such a setup for coronary indication stents.

疲劳预处理的模拟使用试验

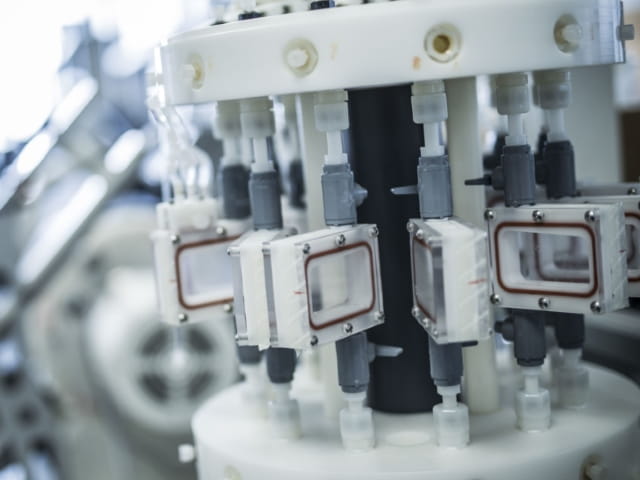

While tracking fixtures are routinely used for simulating device deployment in vitro, one application that is not discussed often is their use for fatigue preconditioning. There are typically a few thousand cycles of fatigue loading applied to the device as preconditioning, but how about preconditioning of the device before it is deployed in the fatigue test instrument?

疲劳试验仪器通常采用笔直或分叉的模拟血管,这些血管可能无法完全模拟设备在体内的曲折展开路径。疲劳试验前的预处理装置是解剖学上正确的体外固定装置发挥作用的地方。夹具有助于预处理设备,这些设备将在生理相关的环境中进行疲劳试验,通过几个循环的展开和缩回,通常重复5到10次。

In some cases, more complex mock vessel geometries are designed, as we discussed in a recent article on复杂的Intravascu脉动的耐久性测试lar Devices.However, even these designs may come up short on the complexity of the actual in vivo geometries. Therefore, preconditioning in simulated use environments ensures that devices have been exposed to the forces they will experience in vivo prior to fatigue testing.

Simulated use fixtures and environments

A few standards describe deployment tracking fixtures for specific applications. For example, the aforementioned ASTM F2394 includes engineering diagrams in its appendix that simulate coronary vessels with a moderately difficult degree of tortuosity. According to the standard, the fixture can be used with a guide catheter, a guide-wire and the stent-balloon catheter delivery system to simulate the forces the device will encounter in the clinical setting as it is deployed to the lesion site.

There are several commercially-available simulated use setups for a variety of intravascular devices and indications. However, manufacturers often develop their own custom designs based on their specific device, finite element analysis and computational fluid dynamics modeling. Custom anatomical models are manufactured out of glass or silicone, or 3D printed.

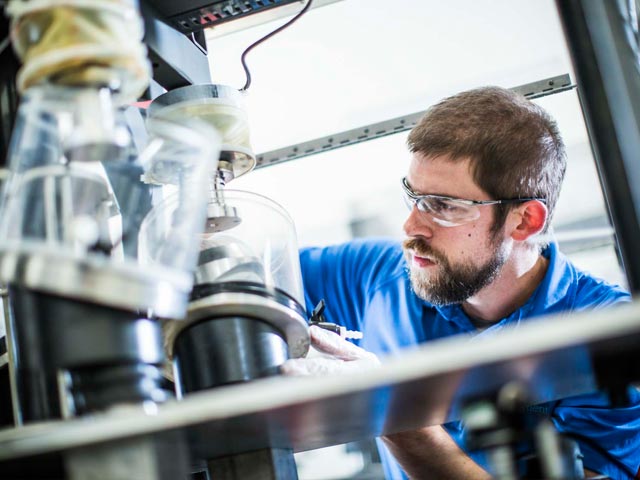

During the simulated use test, in vivo models are immersed in water or saline baths heated at 37°C, and temperature is allowed to equilibrate before devices are deployed. Each device is labeled with a unique identifier for traceability purposes, and labeling continues on to fatigue testing. Devices and delivery systems are closely inspected for any damages or defects prior to and after deployment. After preconditioning in the tortuous path geometry has been completed, devices are ready to be deployed in the durability test instrument for further testing.

需要模拟使用测试吗?

在过去的几十年里,我们的专业人员擅长心血管设备疲劳测试,并参与了许多具有挑战性的设备设计和测试设置。Contact usto discuss how we can help with your test project.

Element拥有世界上最广泛的医疗器械测试范围之一,包括骨科和cardiovascular implants testingtoEMC/EMI product safety testing生物和包装评估。我们致力于以最便捷、高效和快速的方式满足您的所有医疗器械测试需求。

View more articles aboutMore Sectors

通过网站找到与您相关的文章Nucleus

making certain for nearly 190 years

更多来自元素

High Speed Stent and Graft Testers

我们的医疗器械制造客户经常面临着将产品推向市场的短时间挑战。

read More

Test Protocol for Medical Devices

A protocol and plan will mitigate your risk, prevent confusion, set clear expectations, and preserve the necessary information for future reference and use.

Read More

Medical Device

作为一个全面的测试合作伙伴,从机械测试和环境模拟到EMC和无线设备测试,您将享受到单一供应商来源的好处,以满足您的所有测试需求。

Read More

心血管设备测试

元素specializes in a wide range of testing for cardiovascular devices, such as stents, grafts, occluders, catheters, heart valves and pacemaker leads.

Read More