Article

国防和航空航天EMC Testing at Element

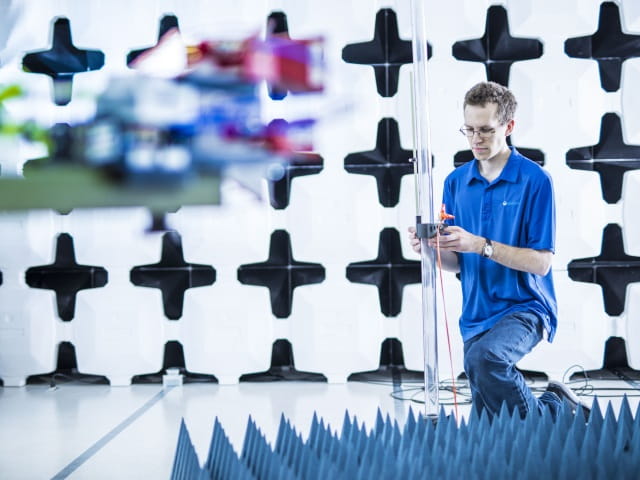

To meet the needs of our Defense and Aerospace industry customers, Element offers accredited MIL-STD-461 and RTCA DO-160 testing at multiple locations across the US and UK. Our team of experts understands the unique requirements for Defense and Aerospace Electromagnetic Compatibility (EMC) testing, and will work with you to provide the testing that you need for your projects.

About EMC test requirements

EMC testing requirements are based on the environments of intended use. Because Defense and Aerospace products often need to operate in severe conditions, and are critical products in nature, thorough testing is essential. Due to the variability of the intended environment, susceptibility test levels and emissions limits will differ based on where the product is installed and used.

For military installations, different test levels and limits are specified for installations on ground-based equipment, aircraft, ships, and submarines. Additionally, there are distinct limits for installations or use above or below decks on ships, and inside or outside an aircraft.

For civil aircraft equipment, susceptibility test levels vary greatly based on the function of the equipment. Critical navigation equipment is subject to much more stringent levels than a coffee maker or entertainment system. Emissions limits are based primarily on the location of the equipment inside or outside the fuselage, relative to the antennas used for the communications and navigation systems.

Defense and aerospace test standards

MIL-STD-461

The EMC standard for military subsystems and equipment in the US is MIL-STD-461. Prior to MIL-STD-461, each branch of service had its own set of EMC requirements and tests. The original MIL-STD-461 was published in 1967 and the most recent edition is MIL-STD-461G, published in 2015. Although MIL-STD-461 is required for US military programs, it is also the de facto EMC standard for defense projects all around the world, with a few exceptions.

MIL-STD-461 includes multiple test methods broken into four parts:

- Conducted emissions

- Conducted susceptibility

- Radiated emissions

- Radiated susceptibility

Conducted and radiated emissions tests are always required for avionics, but the applicability of any susceptibility test method is usually defined by the nature of the installation and purpose of the equipment. In general, more vital avionics (communication, navigation, flight control) will require more tests at higher levels.

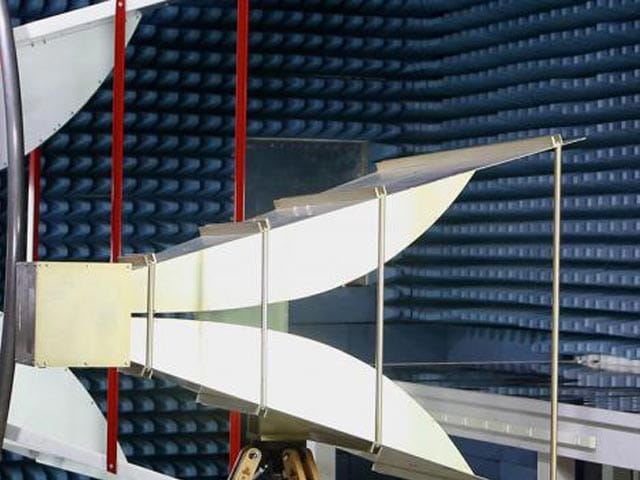

RTCA DO-160

The EMC standard for equipment installed on civil aircraft (avionics) in the US and a large part of the world is RTCA DO-160.

DO-160 was first published by RTCA in 1975, with the most recent edition being DO-160G, published in 2010. In Europe, the document is published as ED-14G, by EUROCAE, the sister organization to RTCA. Both documents are identical in all ways except the title.

DO-160, unlike MIL-STD-461, includes environmental tests such as temperature, humidity, vibration, along with the power quality and EMC tests. As with MIL-STD-461, the DO-160 includes multiple test methods for:

- Conducted emissions

- Conducted susceptibility

- Radiated emissions

- Radiated susceptibility

In addition to these tests, DO-160 also includes requirements for power quality and direct effects lightning, which are covered by different standards for military applications. Each military service (Army, Air Force, or Navy) has a different list of required test method based on the application of the equipment.

Element EMC laboratory capabilities

Whether your program is for the military or for civil aircraft, it is important to have a clear understanding of the tests required for compliance before you begin testing. Element’s experts can help you understand which tests you will be required to perform.

Element test laboratories can perform all the tests specified in DO-160 and MIL-STD-461. We offer a full suite of testing that includes:

MIL-STD-461

- Radiated emissions to 40GHz

- Radiated RF susceptibility to 40GHz, at 200V/m

- Transient radiated susceptibility (RS105)

- Conducted emissions, including CE106

- Conducted susceptibility, including CS103, CS104, CS105, CS117, and CS118

RTCA DO-160

- Radiated emissions tests

- Radiated susceptibility (all levels and categories)

- Conducted emissions

- Conducted susceptibility

- Power quality

- Voltage spike

- Magnetic effect

- Induced signal susceptibility

- Lightning indirect effects (all levels and categories)

- Lightning direct effects

Element EMC laboratory locations

Element has laboratories with the specialized chambers, equipment, and engaged experts to provide EMC testing for the defense and aerospace industries in the following US and UK locations:

- Hillsboro, Oregon, USA

- Bothell, Washington, USA

- Bloomington, Minnesota, USA

- Plano, Texas, USA

- Melbourne, Florida, USA

- Oxford, UK

- Wimborne, UK

- Malvern, UK

The importance of an approved test plan

Creating a test plan is the most valuable preparation you can do for testing. Larger military or aerospace contractors require you to have your test plan approved prior to testing to ensure your products will meet their requirements. If you already have a test plan in place, our team can also review your current plan to ensure you are properly prepared for testing.

How to make test prep easier

The sooner you consider testing, the easier testing will be. Element’s military and aeronautical test engineers are here to assist you, whether you need help creating or reviewing your test plan or preparing your products, so you have a better chance of passing testing the first time. Time is financially valuable when it comes to testing, so many of our customers find it beneficial to come in for pre-compliance scans.

The pre-compliance scan

Pre-compliance scans are a great tool to get a feel for how your device will perform during final testing. Stop by one of our locations to run scans for key tests to discover areas that might need improvement. Necessary modifications are much simpler and more affordable to make if they are discovered earlier in your development cycle.

Why trust Element to help you as your testing partner?

Element has over 200 laboratories worldwide. Our engaged experts are here to guide you through the testing processes and bring your products to market sooner. We are Element, a global provider of Testing, Inspection and Certification services for a comprehensive range of materials and products in sectors where failure is not an option.

Contact us todayfor more information about Defense and Aerospace testing at Element.

View more articles aboutMore Sectors

Find related articles to you through theNucleus

Get white papers, updates and event invites

Subscribe to content updates

making certain for nearly 190 years

More from Element

Medical Device EMC Testing

Element is the ideal partner for EMC testing, safety, certification and global approvals of your Class I, II and III electronic medical devices.

Read More

Military Defense Testing to MIL-STD-461 and DEF STAN 59-411

Element has global capacity to provide you with secure and compliant EMC qualification to MIL-STD-461 and DEF STAN 59-411 military/defense standards.

Read More

Marine Equipment EMC Testing

Our test facilities for both EMC and environmental provide a comprehensive portfolio of tests to ensure that whatever your marine equipment is and wherever it's locations, we have a test solution that matches your needs.

Read More

Aerospace EMI/EMC Testing

Element has a proven record of delivering high-volume EMI/EMC testing to meet standards such as RTCA/DO-160 for civil aircraft requirements.

Read More