Article

Personal Protective Equipment (PPE) Testing

The Food and Drug Administration (FDA), Centers for Disease Control and Prevention (CDC), and World Health Organization (WHO) have recently updated their guidelines to ensure Personal Protective Equiptment (PPE) can get to market faster. By issuing new guidance on testing and production for hand sanitizers, medical and consumer masks, medical gowns, and face shields, companies outside of the regularly licensed producers are now helping fill the unprecedented need for PPE.

Element has developed solutions to perform and/or coordinate the required testing for PPE, hand sanitizers, masks, gowns, and face shields, to ASTM F2100, USP 611, and ANSI Z87 standards to help you achieve the certification necessary to get these critical products into the hands of those who need them.

Hand Sanitizer Testing

Following the CDC and World Health Organization’s policy, all hand sanitizers in production are required to undergo USP 611 Method II: Alcohol Determination performed by GC-FID before they can be released to the market.

Element offers alcohol determination testing by GC-FID per USP 611 to verify that at least 70% isopropyl alcohol (IPA) or 60% ethanol is present in the product. Our GC-FID method is the most precise and cost-effective of the methods allowed under USP 611 because it allows direct analysis of the sample matrix. This direct analysis allows our experts to quantify the ethanol or IPA present in the product without extensive sample preparation, reducing your testing cost while providing more precise results.

Element also offers alcohol determination testing byGC-MSto identify any additional compounds that may be present in the product and could be harmful to users.

Our Santa Fe Springs Pharma laboratory can also provide testing of ethanol and isopropyl alcohol against the USP monograph specifications as raw materials intended for use in the manufacturing of hand sanitizer products under US FDA guidelines.

We offer expedited service when needed for alcohol content identification testing.

Medical and Consumer Face Mask Testing

Per FDA guidelines, medical face masks are required to undergo testing per ASTM F2100 methods before they can be distributed for use. Testing also needs to consider the intended use and applicability of the test methods for the desired regulatory submission. Consumer masks only require method 9.5, but methods 9.2 and 9.3 are highly encouraged to verify mask effectiveness.

Element is one of the few testing laboratories that can facilitate all five methods. Our experts can guide you through the process and provide one complete testing report for medical masks.

- Method 9.1 – ASTM F2101 – Bacterial Filtration

- Method 9.2 – EN 14683:2019 – Differential Pressure

- Method 9.3 – ASTM F2299 – Particulate Filtration

- Method 9.4 – ASTM F1962 – Synthetic Blood

- Method 9.5 – 16 CFR Part 1610 -Flammability

While N95 masks are traditionally single-use, the unprecedented shortage has resulted in decontamination efforts to re-use these devices. Element can perform residual hydrogen peroxide testing on new masks to ensure that the client procedure for decontamination does not leave behind residual H2O2.

Face Shield Testing

Per American National Standards Institute (ANSI) guidelines, all face shields must undergo testing to the ISEA Z87.1-2020 specification to ensure safety and effectiveness in preventing eye and face injuries before they can be released to the market.

Element conducts the six critical sections of the specification to ensure the effectiveness of face shields in a medical environment. These sections include:

- Section 5.2.4 – Minimum Coverage Area

- 9.2节,透光率

- Section 9.3 – Haze

- Section 9.6 – Drop Ball

- Section 9.7 – Ignition

- Section 9.17.2 – Droplet and Splash

Medical Textile Testing

Building and Fire Codes require all fabrics and films, including medical gowns, to undergoflame propagation testingbefore they can be released to the market. Because textiles and films provide a conduit for flame spread, they can be significant contributors to the growth of building fires. Assessing their flammability characteristics is crucial to understand whether a fire is likely to start and how the flame will develop.

In addition to assessing flammability characteristics per ASTM F2100 Method 9.5, CAN/ULC-S109, and NFPA 701 Methods 1 and 2, our experts perform water resistance, tensile strength, seam strength, link generation, evaporative resistance, colorfastness, fabric durability, and more to help textile suppliers ensure their medical materials and gowns comply with required safety standards.

For more information on testing requirements for isolation and surgical gowns, please download our free guide below.

The Element Advantage

Element’s dedicated team of experts have years of experience in a wide range of testing services for themedical deviceandproduct certificationindustries to help you meet regulations and ensure that every aspect of your product is properly tested.

For more information on personal protective equipment (PPE) testing,please contact us today.

View more articles aboutMore SectorsFire and Building Products Testing Services

Find related articles to you through theNucleus

resource

Medical Textile Testing Guide

Download our FREE guide to testing requirements for isolation gowns and surgical gowns.

Get white papers, updates and event invites

Subscribe to content updates

nearly 190 years of making certain

More from Element

Medical Equipment and PPE Regulatory Reference Guide

Access our free guide to the proper protocols for US regulatory submission to help ensure your products get to market as quickly as possible and into the hands of those who need them.

Read more

Element lends its support to UK ventilator initiative with free EMC and safety testing

Element is lending its support to the national drive to increase ventilator production in response to the NHS’ urgent demand to treat coronavirus patients in the UK.

READ FULL ARTICLE

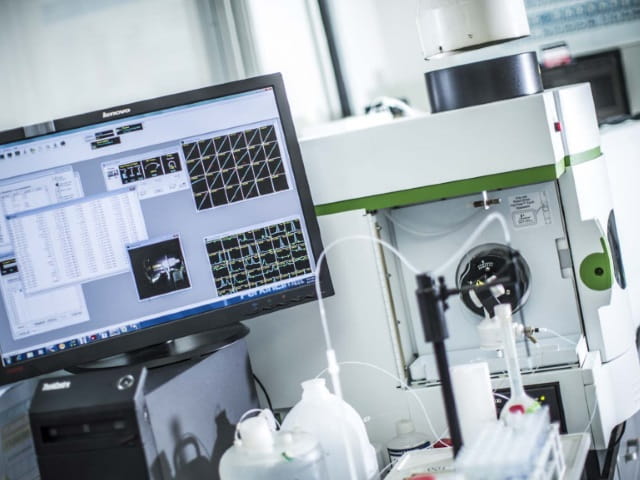

Gas Chromatography Mass Spectroscopy

GC / MS结合两个先进的分析techniques which allow for the identification and precise quantification of volatile and semi-volatile compounds for liquid, gaseous and solid samples.

Read More

Chemical Compatibility Testing for Medical Devices, Materials, and Surfaces

Element can offer automated chemical compatibility testing that gives faster and more reliable results for medical device compatibility with medical disinfectants.

Read more