Article

Thermal, Physical, and Mechanical Properties of Composite Materials

Companies that manufacture final products or parts using composite raw materials must understand each of the individual properties of the different constituent materials before use. This is in addition to understanding the properties of the final part or product prior to installation and is necessary for several reasons, not least to ensure that each material is fit for purpose and to guarantee batch-to-batch consistency.

有一系列的试验方法,可以帮助鉴定和量化复合材料的不同性能,包括热、机械和物理试验。这些试验还可用于预测可能受到各种环境条件影响的材料的寿命。通过应用不同的分析技术组合,也可以识别未知材料。乐动娱乐官网

Thermal properties of composites

Some raw materials used in the manufacture of composite materials can be negatively impacted by the effects of temperature and humidity. It is therefore essential to ensure they are stored within highly controlled environmental conditions prior to use.

当原材料从原材料制造商交付给产品或零件制造商时,必须进行强制性检查,以确保每个材料的批次性能不会受到运输过程的负面影响。在温暖、潮湿的气候或长途快递运输过程中,这种检查过程特别重要。例如,从英国运往印度尼西亚的材料可能会暴露在外界温度下,这可能会促进材料固化或使材料吸收水分。乐动体育网址多少乐动娱乐官网

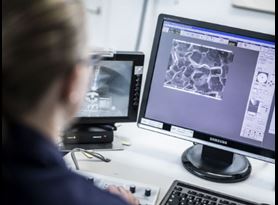

Differential Scanning Calorimetry (DSC)is one of the common tests used to check the cure and confirm the material’s thermal properties. DSC is one of the most important test types when discussing quality control, especially where the supplier has built up a sufficiently large database of previous results with which to compare against. DSC can provide information on the physical structure of the material via important thermal transitions such as glass transition temperature (Tg) [link], melting temperature (Tm), crystallization temperatures, percent crystallinity, enthalpy of melting and crystallization, specific heat capacity (Cp) and oxidation induction time (OIT).

Oxidation Induction Time (OIT)is an assessment of the time for which an antioxidant system present in the polymer inhibits oxidation while the material is held at a specified temperature or heated at a constant rate in an oxygen atmosphere. Antioxidants are often added during the formulation to hinder the aging caused by oxygen and to increase the material’s lifespan. OIT can be used to study the degree of polymer aging throughout the material’s lifetime due to exposure to heat, oxygen, light, and radiation.

Dynamic Mechanical Analysis (DMA)是一种可通过粘弹性力学特性提供材料物理结构信息的技术。该试验允许材料在温度或频率扫描期间对正弦力的响应得到。DMA可用于测定复合材料的力学性能(机械模量或刚度和阻尼)以及胶粘剂的重要热转变,如玻璃化温度和聚合物和复合材料的固化程度。DMA和DSC测试也可以一起使用,以提供一个简单、快速的测试程序,以比较所提议的替代新原料。乐动娱乐官网

Thermogravimetric Analysis (TGA)can be used to provide information on the material’s chemical and physical structure via thermal decompositions. TGA provides information on the temperature and rate of decomposition of materials and the number of volatiles and fillers they contain. With advanced analysis software, characteristic temperatures such as melting points and decomposition temperatures can also be evaluated.

热机械分析(TMA)can be used to look at the material’s coefficient of thermal expansion (CTE). This technique enables the deformation of a material under a constant load to be measured while the material is subjected to a controlled temperature program. This is important to quantify because the expansion or contraction of a material under various conditions can cause issues during the manufacture of a new part or when the material is in final use. Quantification at an early stage can help to resolve any possible future-fit and assembly issues.

Mechanical properties of composites

A basic tensile strength test will provide an indication of the fundamental mechanical properties of the composite material. These results can then be used as a quick test to check the material integrity and ensure the manufacture conforms to a ‘fit for purpose’ standard. The tensile strength can also be used to provide an easily comparable indication of batch-to-batch material quality.

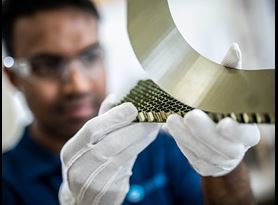

Climbing drum peel tests can be used to provide information on the suitability of potential raw material used in composite sandwich materials. In this test, thin monolithic facing sheets are bonded to a central honeycomb core. The facing sheet is peeled from the core to determine the peel resistance of the adhesive bond. This test is ideally looking for failure in the honeycomb and to demonstrate that the adhesive is the strongest material part and therefore fit for purpose to be accepted for further use.

Most thermoset resins, adhesives, and prepregs have a limited shelf life under cold storage conditions, which becomes even shorter when the temperature is increased to room temperature. For this reason, the times and temperatures of material exposure are carefully monitored and recorded. However, even with careful management, it is important to quantify the suitability of adhesive batches upon purchase from the supplier. This can be achieved through lap shear testing, which involves bonding two composite or aluminum plates together using the adhesive and pulling in tension.

作为抗利尿激素esive batches can be accepted or rejected for use based on the lap shear strength results, it is crucial that the samples are carefully prepared, and the test alignment is correct. A lap shear test can also be used to check the properties of an expired material, potentially providing data to support an extension of the adhesive’s shelf life.

复合材料的物理性能

Density, volatile material percentage, resin percentage, fiber percentage, and percentage of porosity or void content are important basic material physical properties of composites that need to be quantified through constituent content testing before the raw material reaches the next stage of production.

There are extremely strict limits, usually set by the end-user, with regard to the required results, which have been calculated to provide optimized properties. The quantification of the material density is of particular importance as this can provide information on the level of crystallinity present. Molecules in the crystalline phases pack together more tightly than those in the amorphous phases, providing the material with a higher density.

Fiber areal weight and prepreg areal weight are often required to be checked when signing off on the quality of newly purchased raw material. This is to ensure that the mix ratio between the fiber and resin in the prepreg is optimized to provide the desired end properties and to avoid the addition of any unnecessary weight to the end component when used in production.

Fourier transform infrared spectroscopy (FTIR)provides information on the chemical structure of a material. This technique is employed to obtain an infrared spectrum of a solid, liquid or gas, which can be used to characterize the component. The different chemical bonds between atoms give different signals, with each material having a unique FTIR spectrum. FTIR can be used as a material quality control test to ensure that the chemical composition is right. It can also be used to investigate an unknown material by comparing the unknown sample spectrum with stored library spectra. Any suspected heat damage can be detected using this technique as the chemistry of the material may change after exposure to elevated heat.

凝胶Permeation Chromatography (GPC), also known as Size Exclusion Chromatography (SEC), is a technique that can be used to separate the polymer molecules in the sample according to chain length. The polymeric molecular weight distribution (MWD) can be determined using GPC. It can be important to quantify this particular material property because it relates to the physical characteristics of the final material, such as tensile strength and crack propagation characteristics. The polymer manufacturer will have an optimized weight range where the idealized properties are balanced. Examples of such properties include viscosity which is important for processability, sample strength, toughness, and crack resistance.

The Element advantage

Element提供了完整的测试套件,以帮助材料供应商和制造商了解复合材料的原材料性能。我们的专家将为常规测试和需要专门分析设备的测试准备和测试样品,如DSC、TGA、TMA、DMA、FTIR和GPC。Element丰富的经验,提供咨询、准备、测试和认证原材料,使我们的客户能够乐动娱乐官网确保交付的材料批次与预期相同。

For more information on how to qualify and quantify the thermal, chemical, and mechanical properties of composite materials,contact an expert here.

通过网站找到与您相关的文章Nucleus

making certain for nearly 190 years

更多来自元素

Composite Raw Material Testing

元素的复合原材料测试有助于制造商了解用于制造复合产品的成分的物理、热和机械性能。

Read More

Composite Fatigue Testing

Whether testing to a specific standard or developing a custom program, Element’s experts are ready to assist with your composite fatigue testing needs.

Read More

复合材料损伤容限试验

Element offers a variety of test methods that provide manufacturers with more insight into their composite materials’ damage tolerance and resistance.

Read More

Composites Testing

Find out how Element helps its customers to develop, test and qualify their composite materials to ensure that these complex, cutting-edge materials are safe, quality, compliant and ultimately fit for purpose.

Read More