元素提供各种裂缝韧性和骨折机械测试服务,以帮助您估算组件的生命,减少昂贵的维修,改善设计,延长组件的预期寿命。

Fracture toughness testing is amechanical test methodused to determine the energy needed to initiate and cause failure within a material. It can also be used in conjunction with疲劳试验那corrosion testing那andelevated temperaturesto determine the useful life of the material under different conditions.

我们的骨折韧性测试服务

我们的专家使用先进的技术和设备,提供了有价值的洞察材料性能,帮助您对金属,非金属和先进材料的安全性,健身和长寿进行了关键决定。乐动娱乐官网作为骨折力学和机械测试的单源提供商,我们可以帮助创建一个测试程序,为您提供对您的产品和材料的信心。乐动娱乐官网

Our services include characterizing fracture toughness through single point critical values (CTOD, J integral, and K) as well as tearing resistance diagrams (J-R and CTOD-R curves), following the international standards including BS 8571, ISO 12135, ASTM E1820, ASTM E1921.

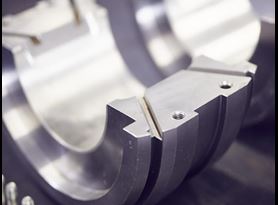

Specimen geometries

元素配备良好的,用于对广泛的标本尺寸和裂纹几何形状进行断裂韧性测试和分析,包括但不限于:

- 紧凑的张力(CT)

- Middle Tension (MT)

- Single-Edge Notched Tension (SENT)

- Single-Edge Notched Bend (SENB or three-point bend)

- 延长紧凑张力(ECT)

- 中心破裂的张力(CCT)

- 表面裂纹张力(SCT)

- 模式I,II和III乐动娱乐官网载荷下的复合材料

Materials class and fracture mechanics test capabilities

我们的骨折力学专家使用先进的计算机控制的伺服液压测试框架测试高强度的黑色金属剂,有色剂和复合材料。乐动娱乐官网再加上几十年的经验和许多成功的应用程序,我们的先进设备控制,流程和数据采集方法允许我们引导您甚至最复杂的测试结果。

还有可能创建自定义骨折测试分析,并适应特定应用或环境对非标准断裂力学测试协议的任何请求。

元素优势

我们的订阅专家提供了对材料绩效的宝贵洞察力,帮助制造商对金属,非金属和先进材料的安全性,健身和长寿进行了关键决定。乐动娱乐官网作为机械测试服务的单一来源提供商,我们可以帮助创建一个测试程序,为您提供对您的产品和材料的信心。乐动娱乐官网

We perform fracture analysis for a wide range of industries, from Transportation, Aerospace, and Defense suppliers to Oil and Gas, Power Generation, and Infrastructure.

有关裂缝韧性测试或接收报价的更多信息,联系专家today.

近190年的肯定

More from Element

疲劳试验

Find out how Element's fatigue testing labs help companies meet quality requirements and create safer, stronger, more successful parts and products.

阅读更多

Engineering Critical Assessment (ECA)

Our world leading Fitness For Service (FFS) for the Oil & Gas Sector

READ MORE

冶金测试

了解元素的冶金测试服务范围,包括显微镜,腐蚀评估,硬度和现场服务。

阅读更多

Fracture Mechanics Download

Read our article to learn the different test methods and sample geometries used to determine fracture toughness.

阅读更多